Projects

Mass Simulator for Collins Aerospace

In early 2020 I designed a mass simulator for my team at Collins Aerospace. This simulator mimicked the approximate dimensions, center of gravity, and weight of another piece that was not yet available. However, vibration testing had to be completed, so the simulator was required to begin collecting baseline data.

The brass blocks and the flat steel plate allowed for the center of gravity to be adjusted in all three axes. I also designed the test fixture used to connect this prototype to the vibration plate. The bottom plates had to be angled to account for a 7° adjustment in the final product.

This mass simulator is currently being used for testing. While designing this I gained valuable experience with PTC Creo, and understanding how to design for manufacturability.

|  |  |

|---|

Trash Cleaning Robot

Cornerstone of Engineering Class

My cornerstone of engineering class tasked each group to solve a real world problem. My group decided to tackle littering on beaches. We designed and prototyped an autonomous beach cleaning robot, and included custom made 3D printed parts.

The robot had two wheels and a mechanical sweeper at the front. The main compartment was made of mesh to allow sand to filter through, but to hold the trash. It included a distance sensor to prevent collisions with people or beach umbrellas. It also allowed the user to input the area required to be cleaned.

I focused on designing the chassis, which required prototyping from cardboard to wood. I also designed a custom part in SolidWorks to connect our sweeper to our servo motors.

This project forced my team to iterate designs and prototype very rapidly since we were under a time constraint, which, while stressful at the time, was a valuable learning experience. It successfully completed its goals of driving on sand and picking up sand.

The trash cleaning robot on sand!

An extreme challenge was to get the robot to move correctly on sand, as this was a beach cleaning robot after all. It took a lot of trial and error, but it eventually worked.

The main issue was correcting the amount of power each servo motor produced, since the friction in the sand affected each wheel differently. However, trial and error calibration was our best idea to fix this.

In the future, I would probably not choose to use servo motors, as they were not powerful enough to overcome the friction of the sand. Since speed was not a priority, a stepper motor would have been a better choice because of the amount of torque they produce at low speeds.

|  |  |

|---|---|---|

|

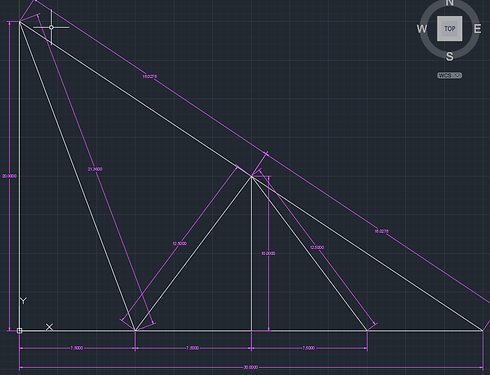

Truss

This truss was a group project for my statics class. We were given limited time and a strict length requirement of 30 inches.

The truss was calculated to support 210N, well over the project goal of 150N. However, it failed at 140N, most likely due to hasty construction.

Also, the foam was much stronger in tension than compression, so more support should have been added under the bottom pieces, as they were under the most compression.

AutoCAD design

This was our final design before construction, with all of our measurements.